High temperature, high pressure and low bath ratio gas-liquid dyeing machine

product details

Performance characteristics

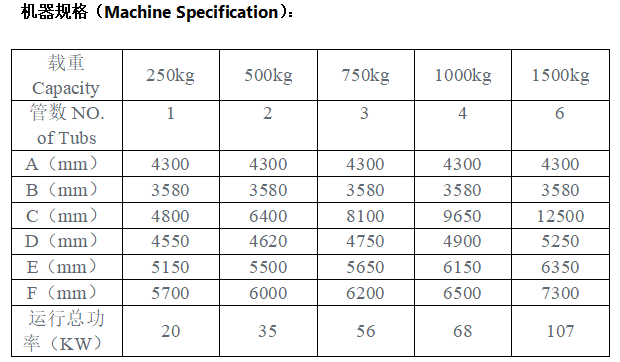

technical parameter

Hsqy-168 dyeing machine with high temperature overflow and gas-liquid combination is the technical crystallization of our company's years of experience in the dyeing and finishing equipment industry. Hsqy-168 not only has the advantages of air flow dyeing machine, but also has better dyeing stability than air flow dyeing machine. Because HSQY-168 can be used as both overflow dyeing machine and gas-liquid dyeing machine, it consumes less power than air flow dyeing machine and general gas-liquid dyeing machine. One machine dual use, ultra-low bath ratio, really achieve energy conservation and environmental protection.

Features of high temperature, high pressure and low bath ratio gas-liquid dyeing machine:

1. Small bath ratio: dyeing bath ratio can reach 1:4

2. Dyeing liquid levelling device: Specially designed feeding system can ensure the effect of fabric levelling at low bath ratio.

3. High reproducibility: programmable metering, accurate quantitative feeding system, fabric cycle time control, adjustable fan and nozzle pressure.

4. Good dyeing stability: due to the use of overflow nozzle dyeing, it is not easy to produce colored flowers when dyeing sensitive colors, and there will be no pipe difference.

5, no crease: Due to the use of fan driven fabric operation, strong airflow can penetrate the fabric, achieve the purpose of eliminating the internal stress of the fabric, the fabric has no crease.

6. Energy saving and high efficiency: dyeing cotton consumes 50-60 tons of water per ton, saving more than 50% of water than traditional dyeing machine, more than 40% of auxiliary agent and steam, and greatly reducing the cost of sewage treatment.

7, independent water supply cleaning device: because of the use of independent water supply, cleaning water pressure can be higher and stronger, faster and cleaner washing cylinder.

8. Overflow and gas-liquid dual use: it can be dyed by overflow and can be dyed by gas-liquid, which can effectively solve the problem of colored flowers and creases generated in the dyeing process of the fabric.

Technical data:

Dye bath ratio: 1:4

Distribution speed: up to 380m/min

Working temperature: 140℃

Working pressure: 0.35mpa

Temperature rise rate: 20℃-100℃ average 5℃/min

100 ℃ to 130 ℃ average 2.5 ℃ / min

(Dry saturated steam pressure is 0.7mpa)

Cooling rate: 130℃-60℃ average 2.5℃/min

(cooling water is 3bar at 25℃)