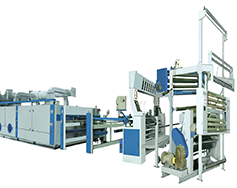

The stenter machine

product details

Performance characteristics

technical parameter

Hsmfs-328/329 double duct tensioning and shaping machine designed by Hongshun is suitable for finishing all kinds of textile fabrics, especially elastic fabrics and sensitive fabrics. This model has high efficiency, low energy consumption, independent uniform temperature box design, and gives the fabric low tension. The manufacturer of the tensioning machine adopts some imported electrical control equipment, such as the horizontal aligning device of EL company and the German reducer motor to ensure the stability of the product. As well as pressure sensor, PLC, touch screen and other equipment to enhance man-machine interaction, the equipment has strong versatility, all natural fiber and man-made fiber woven fabrics, knitted fabrics and warp knitted fabrics can be treated with this equipment. The vehicle speed is set at 5-100 m/min. Suitable for dewatering, finishing, drying, baking and heat setting of knitted and woven fabrics.

Main technical parameters

Form: hot air circulation, single layer horizontal

Carriage: Right-handed (or left-handed)

Nominal width (mm) : 1800, 2000, 2200, 2400, 2600 (narrow range series)

2800, 3000, 3200, 3400, 3600 (Wide width series)

Amplitude modulation range (mm) : 700-1600 700-1800 700-2000 700-2200 700-2400

700-2600 700-2800 700-3000 700-3200 700-3400

Nominal speed: 100m/min (speed range: 5-100m/min)

Range of overfeeding rate: positive overfeeding 30%, negative overfeeding 10%

Oven temperature: 100-230℃

Heat sources: Carrier heat oil, gas (city gas, natural gas, water gas, LPG), electricity, high pressure steam

Hold cloth form: pincus clip

Fall cloth form: single pendulum or pendulum, roll double fall cloth or roll

Edge detection: high precision infrared edge detection

Guide form: oil-free steel guide or cast iron guide

Number of baking sections: 4-10, each section is 3m long

Dimensions of the drying room :(1344+n×3000) mm+ (W+1816) mm×1737mm

Machine dimensions :(16115+n×3000) mm+ (W+2500) mm×2300mm

Installed power :(55+n×15) KW (excluding electric heating power)

The process flow

Open width feeding → thread broadening → infrared alignment → rolling → round winding → underfeed → overfeed on top → overfeed on top → peeling side → infrared detection side → upper needle edge → pulping side → stretching or hot setting → cold air cooling → cutting side and suction side → stripping → tilting off cloth or small beating