Our company has rich experience in the transformation of molding machine, medium temperature and medium pressure steam. The suitable design scheme is given for different fabric temperature requirements and different steam conditions.

Our company's medium-temperature and medium-pressure transformation project has the advantages of fast heating, low flow, etc., especially in the recycling of steam condensate water in the leading level in China, and has obtained two national patents.

After-sales service: product quality and after-sales service is the basis for enterprise survival and development, from the beginning of establishment, we have established the "honesty, good quality, customer first" corporate culture, in order to complete this commitment, we established a bear hardships and stand hard work, skilled professional team, years of service in the first - line. As long as the users interested in our technology can come to our company to visit, negotiate, for all our users, I; The company can send people to guide and equipment maintenance, for you to relieve the worry.

Our company's concept of medium-pressure and medium-pressure steam transformation: medium-pressure steam transformation project has only one key point and difficulty, that is, how to improve the steam heat utilization rate under the condition of ensuring the process temperature, the high utilization rate will save the flow, and the low utilization rate will cost the flow.

The heat of medium pressure superheated steam consists of three parts: superheat heat, saturated phase transition heat and condensed water heat. Among them, superheat heat accounted for about 10% of the total heat, saturation phase transition heat accounted for about 70% of the total heat, condensed water accounted for about 20% of the total heat. It can be seen from the above that most of the medium pressure steam is phase change heat, also known as latent heat, and the saturation temperature is related to the pressure, so the important index of the medium pressure steam is the pressure, the superheat has little influence on the steam, the overheat is too high, but will affect the temperature rise due to the poor thermal conductivity of the superheat steam.

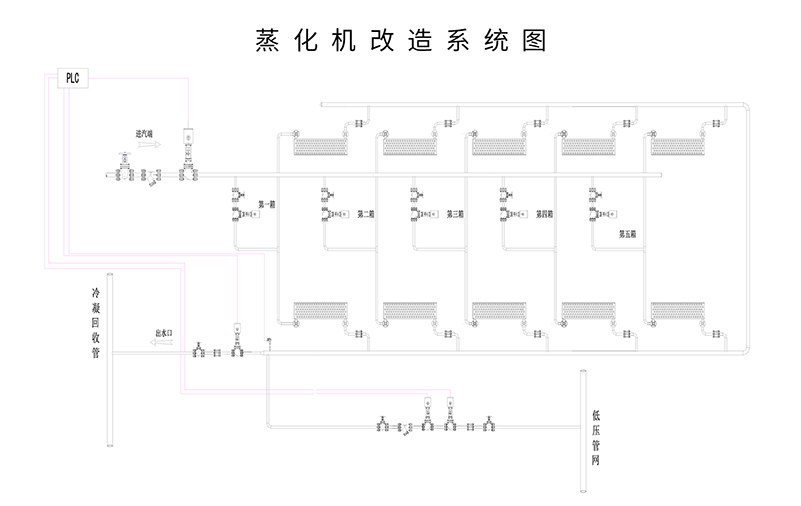

The steam system reform of our molding machine

The following are the defects of the peers in the design of medium pressure steam:

The steam direct discharge method is that the medium pressure steam flows through the heat exchanger, enters the vapor separator after decompression, and enters the low-pressure steam pipe network. In this design scheme, due to the high pressure and fast flow rate of steam, the latent heat of steam may not be fully utilized before flowing out of the heat exchanger. The result is high flow and temperature difference.

2. With the steam trap, due to the high steam pressure, the boiling point of water is also high, under the pressure of 3.0mPA, 230 ° C is the state of water.

Such high temperature condensed water is still available on the equipment, if the use of steam trap condensed water heat utilization will be greatly reduced, the flow is not small, and in this working condition. The failure rate of trap is high, which greatly increases the maintenance cost.

3. With throttle valve, with throttle valve will only limit the effect of steam flow, and ignore the production process, only in a fixed process and fixed fabric under the condition of a record to a role, traffic basic depends on the size of the throttle valve opening size, but the size of the scour hole under long-term steam also subsequently grow big, traffic also slowly.

4. Save about 15% steam energy consumption than any other machine in the same industry.

The above are several schemes commonly used in the market, which rely on mechanical hardware to control the flow rate and improve the steam utilization rate, but it is not ideal, and the medium pressure steam has very high requirements on the hardware, greatly increasing the use cost and maintenance cost. Because our company has a deep understanding of the working condition of medium pressure steam, optimize the pipeline structure and carry out automatic flow control.

Our company's mechanical medium pressure steam control system has the following advantages in the industry:

1 easy to operate, heating machine heating - heat preservation - flow control, etc. All are one-button operation, automatic control, avoid operators frequently switch on and off the valve trouble, and can temporarily stop or change the fabric limit to reduce the waste of steam.

2. The system has fast heating and low flow rate. Steam heat efficiency is high, and adapt to the shaping process of various fabrics, steam intake can be free switch between low pressure and medium pressure steam, return water and return steam can be selected, customers can select specific conditions, flexible and convenient.

3. Reasonably design and optimize the medium temperature and pressure pipeline, greatly increase the service life of manual valve and automatic valve, and avoid the increase in flow caused by valve core wear caused by long-term use.

4. The system has the automatic switching function between the energy-saving mode and the high-temperature mode, which can reduce the steam flow to a limited extent under the condition of ensuring the fabric process.

Address: Jinshang Industrial Zone, Shishi City, Fujian Province Tel:158-8087-1387 Email address:zhangqun068@gmail.com

本网站所用文字图片部分来源于公共网络或者素材网站,凡图文未署名者均为原始状况,但作者发现后可告知认领,我们仍会及时署名或依照作者本人意愿处理,如未及时联系本站,本网站不承担任何责任。