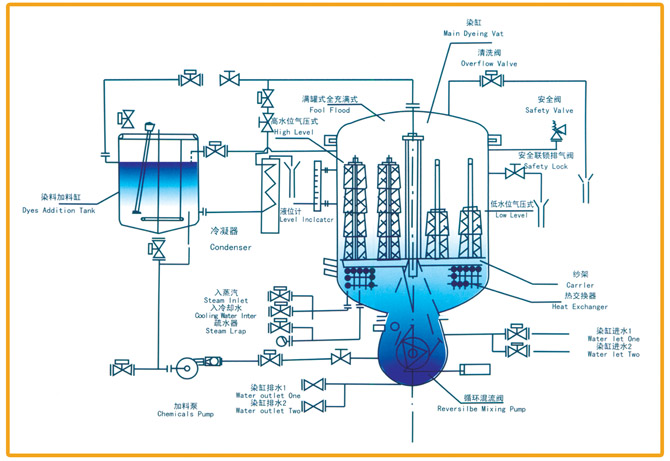

High temperature and high pressure cheese dyeing machine is a new generation of high efficiency and energy saving cheese dyeing machine, 180° flat plate type reversing device, external high efficiency tube shell type heat exchanger, new integrated connection mode of centrifugal pump.

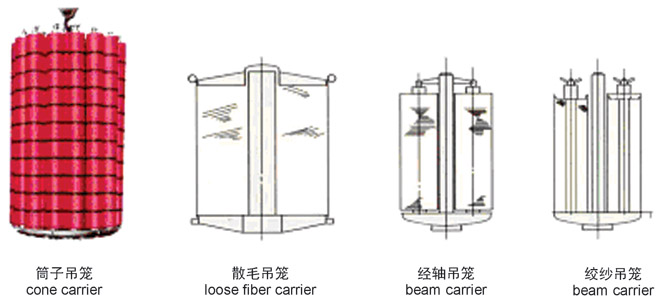

The smaller bath ratio is 1:6. Compared with the domestic and foreign conventional models, the structure is more compact, the bath ratio is lower, the energy is less, the use cost is lower. Suitable for dyeing and before and after treatment of polyester and blended fiber bobbin at high temperature; It is also suitable for dyeing and before and after treatment of cotton, hemp, acrylic, wool and other fibers at room temperature. Different dyeing cages can be used for dyeing and before and after treatment of various types of fibers such as woolen sliver, suspended (or stacked) Hank yarn, loose yarn, silk cake (viscose), nylon zipper, adhesive tape and warp yarn.

The high temperature and high pressure yarn dyeing machine has the following advantages:

■ Integral heat exchanger, centrifugal pump and 180° flat plate reversing device, no external circulation pipe, saving 20% of space.

■ High efficiency and energy saving external novel heat exchanger.

■ Main pump motor frequency control, stepless flow control, according to the process curve to meet the requirements of synchronous dyeing.

■ Unique stable and reliable reversing device, when the liquid flow reversing, the main pump does not stop, increase the number of liquid flow cycle.

■ Advanced computer controller can display temperature curve, step and output at the same time. Automatic control of quantitative feeding, water intake, drainage, heating, constant temperature, cooling and cleaning

And so on meet the dyeing process requirements. Central centralized control system can be connected. Improve dyeing quality.

■ Low bath ratio variable load (1:6-1:10) saves dyes, chemical auxiliaries, steam and water, less sewage discharge.

Standard structure

■ The dye VAT and all parts in contact with the dye solution are made of high quality stainless steel.

■ High efficiency novel centrifugal pump or high efficiency mixed flow pump, depending on the fabric, can control the flow stepless.

■ Vertical cylinder block, fast locking cylinder head with balance hammer device and cylinder switch. Cylinder head electrical interlock device (qR241C-75 above cylinder head with weight balance switch).

■ Plate-type flow commutator with automatic control of commutator.

■ Master cylinder automatic pressure relief device (air cushion type).

■ Open type feeding barrel and quantitative feeding.

■ High precision induction differential pressure sensor control level (air cushion type).

■ Advanced microcomputer programming controller.

According to the technology

1. Design pressure: 0.44mpa

2. Working pressure: 0.4mpa

3. Design temperature: 140℃

4. Operating temperature: 135℃

5. Heating rate: 20℃ ~ 130℃ for about 30 minutes (saturated vapor pressure is 0.7mpa)

6. Cooling rate: 130℃ ~ 80℃ for about 20 minutes (cooling water pressure is 0.3mpa)

Any option

■ Equicapacity preparation cylinder, delivery pump and stirring system with direct heating device.

■ Various yarn frames, such as: bobbin, loose wool, skein, zipper, warp shaft, etc.

■ High temperature discharge.

■ Proportional progressive feeding and proportional heating system.

■ No-load yarn tubes and their fittings.

■ Second intake and second discharge.

■ Main pump flow control system.

■ Bobbin dyeing accessories. Such as: yarn tube, intermediate gasket and self - locking head.

■ Rod lifting and boom type yarn unloading device

Want to understand about the high temperature and high pressure dyeing machine and cheese dyeing machine, you can call to consult The Shishi Hongshun Printing and dyeing machinery Manufacturing Company.

Address: Jinshang Industrial Zone, Shishi City, Fujian Province Tel:158-8087-1387 Email address:zhangqun068@gmail.com

本网站所用文字图片部分来源于公共网络或者素材网站,凡图文未署名者均为原始状况,但作者发现后可告知认领,我们仍会及时署名或依照作者本人意愿处理,如未及时联系本站,本网站不承担任何责任。