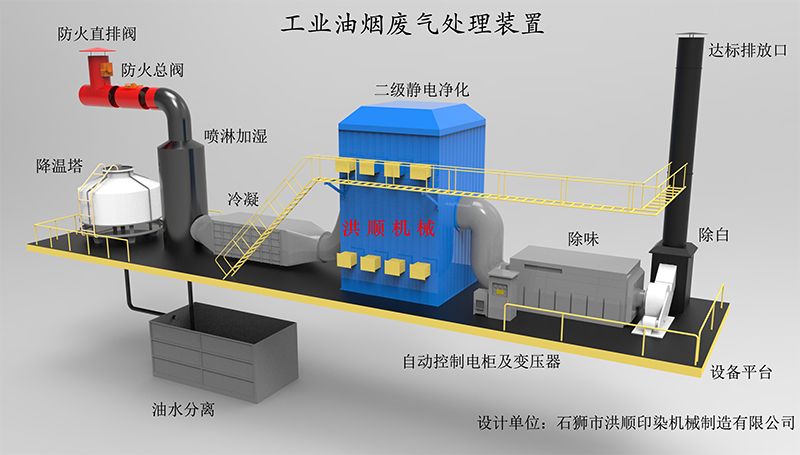

Automatic industrial waste gas treatment equipment process flow: industrial waste gas - water film treatment - filtration condensation - two electrostatic - odor - white - standard discharge

※ The exhaust gas of high-temperature lampblack is connected to the stage 1 treatment section through the flue duct (spraying and humidifying treatment). The flue gas is fully in contact with the high-pressure water mist to wash away the large lampblack, particulate matter and primary cooling.

※ The flue gas reaches the stage 2 treatment section (filter and condensate section) and is further filtered and cooled through multiple filters and condensators to achieve the state and temperature requirements suitable for high voltage electrostatic work.

Does smoke reached level 3 processing period of static (level 2), after a high voltage electrostatic adsorption oil removal, flue gas emission cathode in the high voltage electric field of electronics, as well as by the collision of air molecules and the anion to capture the lampblack, oil mist particles, particles charged, recycle electric fields of the charged particles adsorbed by anode, in order to achieve purification purposes.

※ The flue gas passes through the stage 4 treatment (odor removal device) to remove the unpleasant odor from the flue gas.

※ The flue gas enters the level 5 treatment box (high voltage electrostatic concentrated purification box), and is discharged after deep purification to the standard

Application fields of Industrial waste gas treatment in Fujian:

Hongshun designed and developed HS series automatic cleaning device for fume exhaust purification treatment widely applicable to:

Textile printing and dyeing industry: setting machine, ironing machine, singeing machine, printing machine, flocking machine and other lampblack waste gas purification treatment;

PVC artificial leather, PVC gloves, flocking plastics (POP, DBP, DINP, etc.), VOCs furniture industry, spray paint industry, plastic industry, petrochemical industry, biological manufacturing industry, food additives and printing industry.

Working principle of the low and high pressure electrostatic: industrial waste gas treatment plant using high voltage electrostatic principle, main is to use the cathode in the high voltage electric field emitted electrons, and by the collision of air molecules and the anion to capture the lampblack, oil mist particles, particles charged, recycle electric fields of the charged particles adsorbed by anode, in order to achieve purification purposes.

Address: Jinshang Industrial Zone, Shishi City, Fujian Province Tel:158-8087-1387 Email address:zhangqun068@gmail.com

本网站所用文字图片部分来源于公共网络或者素材网站,凡图文未署名者均为原始状况,但作者发现后可告知认领,我们仍会及时署名或依照作者本人意愿处理,如未及时联系本站,本网站不承担任何责任。